meel bannaan oo bannaan oo A515 gr ah oo 60 ah oo leh 8 muraayado flange indho la'aan ah

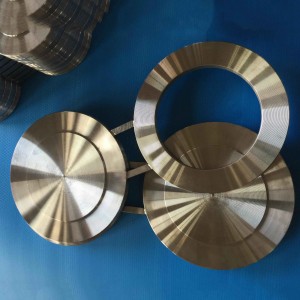

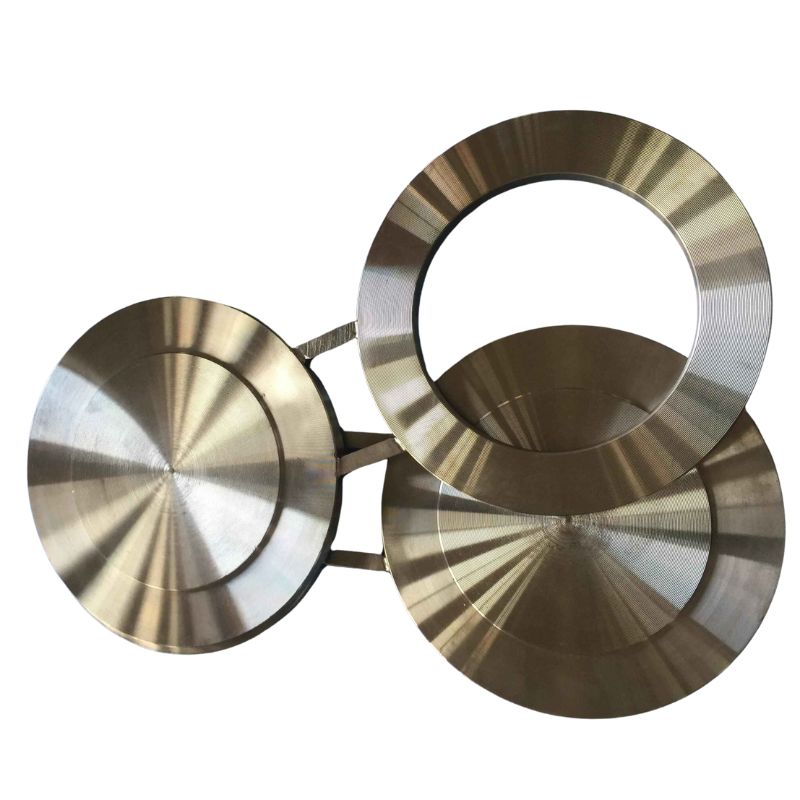

Qalabka Paddle Blank Spacer ee ASTM A515 Fasalka 60, oo loo habeeyay sida Flange-8 Spectacle Blind Flange, waa aalad badbaado iyo go'doomin muhiim ah oo ku jirta nidaamyada tuubooyinka warshadaha. Waxay si xariifnimo leh isugu daraysaa saddex shaqo hal unug oo adag: saxan indho la'aan ah oo adag oo loogu talagalay go'doomin togan, giraangir kala-soocid ah oo loogu talagalay socodka, iyo shabakad isku xiran oo leh gacan "baastoolad" oo dheereysa si loo aqoonsado muuqaal cad.

Birta kaarboonka ee ASTM A515 ee tayada weelka cadaadiska leh ee heerka 60, qaybtani waxay bixisaa xoog iyo cimri dherer heer sare ah oo loogu talagalay adeegga heerkulka dhexdhexaadka ah ilaa kan sare. Naqshadda "shaxda-8" waxay u oggolaanaysaa hawl wadeennada inay si dhakhso ah u go'aamiyaan xaaladda khadka (furan ama go'doonsan) meel fog, taasoo ah astaamo muhiim u ah hababka qufulka/tagout (LOTO) iyo badbaadada warshadda. Iyada oo loo marayo heerarka ASME B16.48, waxay hubisaa waxqabad la isku halleyn karo oo ah xariiq madhan, iyadoo bixinaysa shaabad dhammaystiran oo aan daadanayn marka dhammaadka adag lagu xidho flanges-ka dhexdooda. Dhismaheeda adag wuxuu ka dhigayaa qalab lama huraan ah oo loogu talagalay dayactirka badbaadada leh, tijaabinta nidaamka, iyo isbeddellada habaynta habka ee deegaannada baahida badan.

QEEXIDDA

| Magaca Badeecada | Flange indho la'aan ah |

| Cabbirka | 1/2"-250" |

| Cadaadis | 150#-2500#,PN0.6-PN400,5K-40K,API 2000-15000 |

| Heerka Caadiga ah | ANSI B16.5, EN1092-1, SABA1123, JIS B2220, DIN, GOST, UNI, AS2129, API 6A, iwm. |

| Dhumucda derbiga | SCH5S, SCH10S, SCH10, SCH40S, STD, XS, XXS, SCH20, SCH30, SCH40, SCH60, SCH80, SCH160, XXS iyo iwm. |

| Alaab | Bir aan daxal lahayn:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571,1.4541, 254Mo iyo iwm. |

| Bir kaarboon ah:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24, A515 Gr60, A515 Gr 70 iwm. | |

| Bir aan daxal lahayn oo laba-jibbaaran: UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462,1.4410,1.4501 iyo iwm. | |

| Birta dhuumaha:A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 iwm. | |

| Daawaha Nikkel:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H, C22, C-276, Monel400, Alloy20 iwm. | |

| Daawaha Cr-Mo:A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, iwm. | |

| Codsiga | Warshadaha kiimikada batroolka; warshadaha duulista iyo hawada sare; warshadaha dawooyinka; qiiqa gaaska; warshadda korontada; dhismaha maraakiibta; daaweynta biyaha, iwm. |

| Faa'iidooyinka | kayd diyaar ah, waqti gaarsiin degdeg ah; laga heli karo cabbirro kasta, la habeeyey; tayo sare leh |

HEERARKA CABBIRKA

BANDHIG FAAHFAAHINTA ALAABADA

Qalabka & Dhismaha:

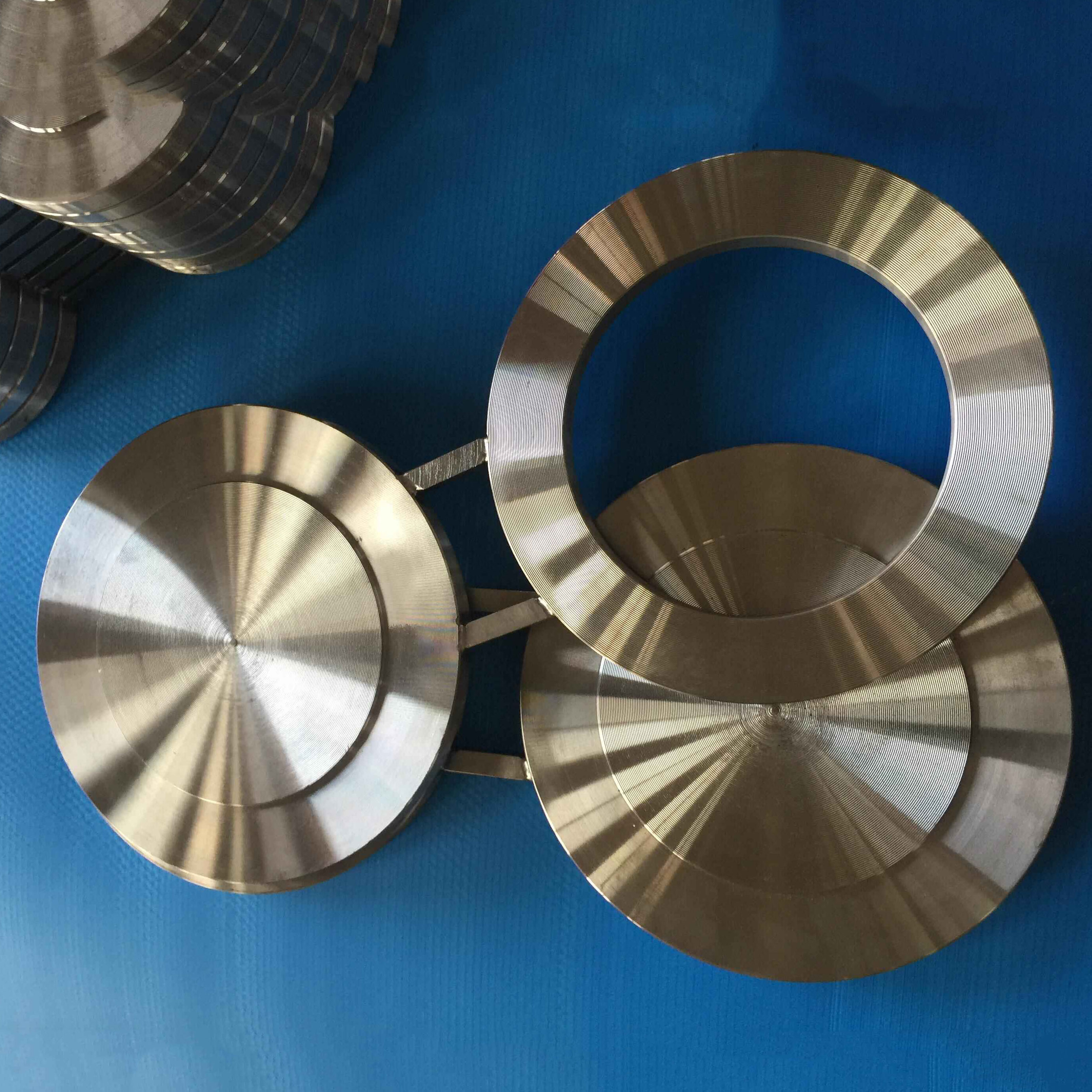

Daahyada muraayadaha waxaa laga soo qaatay birta saxanka ASTM A515 Grade 60, oo ah walxo loogu talagalay codsiyada marinnada cadaadiska heerkulka dhexdhexaadka ah iyo kuwa sare. Waxay bixisaa xoog jilicsan oo ugu yaraan ah 415 MPa (60 ksi) iyo alxan wanaagsan. Adeegga muhiimka ah, A516 Grade 60 ama 70 ayaa la bixin karaa.

Makiinadaha Sax ah:

Dhammaan dusha sare, gaar ahaan wejiyada shaabadaysan ee taabta gasket-ka, waxaa lagu farsameeyaa dhammaystir siman (badanaa 125-250 AARH serrated finish for RF). Godadka boolalka waa la qodaa oo dib loo hagaajiyaa si loo saxo qeexitaannada ASME B16.5, taasoo hubinaysa in si fiican loogu waafajiyo flanges-ka isku-dhafka ah iyo ka hortagga cadaadiska boolalka inta lagu jiro rakibidda.

Tilmaamaha Naqshadeynta:

"Baaskiilada" dhexe waa qayb muhiim ah oo ka mid ah muuqaalka, iyadoo bixisa gacan adag oo loogu talagalay wareegga iyo tilmaame muuqaal oo cad. Badanaa waxaa lagu rinjiyeeyaa midabyo aad u muuqda (tusaale ahaan, jaalle dhinaca kala-qaybiyaha, casaan dhinaca indhoolayaasha) sida waafaqsan heerarka dhirta. Dhumucda labada qaybood ee indhoolayaasha iyo kala-qaybiyaha waxaa loo xisaabiyaa si ay u adkeysato cadaadiska buuxa ee dhuumaha iyo inay bixiso cadaadis sax ah oo gasket ah iyada oo aan la foorarsan.

Shaqayn:

Cutubku wuxuu ku wareegaa boolal u dhexeeya labada flanges ee tuubooyinka. Meesha "furan", giraanta kala-fogeeyaha ayaa la jaanqaadaysa godka tuubada, taasoo u oggolaanaysa socodka. Meesha "xiran" ama "indho la'aanta", saxanka adag wuxuu si buuxda u xannibayaa khadka, isagoo bixinaya meel go'doomin ah oo togan oo ka sarreysa waalka xiran.

Calaamadaynta:

Si joogto ah ayaa loogu shaabadeeyay shuruudaha ASME B16.48, oo ay ku jiraan heerka agabka (A515 Gr.60), cabbirka, heerka cadaadiska, iyo aqoonsiga soo saaraha.

CALAAMADAHA IYO BAAKAD-QAADKA

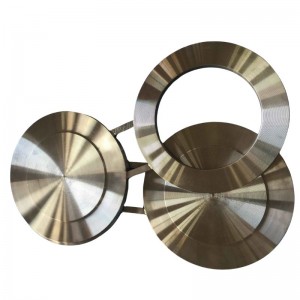

Baakad: Daah kasta oo muraayado ah si gaar ah ayaa loo ilaaliyaa. Wajiyada shaabadaysan ee mashiinka lagu sameeyay waxaa lagu dahaadhay ka hortag miridhku waxaana lagu daboolay dabool balaastig ah ama kartoon ah. Qalabka waxaa markaa lagu duubayaa warqad ama balaastik VCI (Vapor Corrosion Inhibitor) si looga hortago miridhku inta lagu jiro safarka. Cabbirrada waaweyn, sanduuqyada alwaax ee gaarka ah oo leh qalab gudaha ah ayaa la isticmaalaa. Cabbirrada yaryar waxaa lagu dhejin karaa baaldi iyadoo la ilaalinayo geesaha.

Calaamadaynta: Calaamad u adkaysta cimilada ayaa ku lifaaqan, taasoo faahfaahinaysa lambarka qaybta, cabbirka, heerka cadaadiska, agabka, iyo meesha loo socdo. Sanduuqa ama xidhmada waxaa si cad loogu calaamadeeyay calaamado wax lagu qabanayo (tusaale ahaan, "Dhinacan Sare," "Kee Qallalan").

Maraakiibta: Waxaan isticmaalnaa hababka dhoofinta ugu habboon iyadoo lagu saleynayo cabbirka dalabka iyo degdegga - laga bilaabo weelasha badda ee caadiga ah ee dalabaadka waaweyn ilaa rarista hawada ee baahiyaha degdegga ah ee mashruuca. Dhammaan dukumentiyada rarista ee lagama maarmaanka ah (liiska baakadaha, biilka ganacsiga, shahaadada asalka) waxaa si taxaddar leh loo diyaariyey si loo hubiyo in si habsami leh loo nadiifiyo kastamka adduunka oo dhan.

KORMEER

Saxan kasta oo bir ah oo ASTM A515 ah oo heerka 60 ah wuxuu maraa shahaado dhammaystiran oo agab ah. Waxaan sameynaa falanqayn spectrochemical ah si loo xaqiijiyo in halabuurka kiimikada uu buuxiyo shuruudaha darajada, oo ay ku jiraan kaarboon, manganese, fosfooraska, sulfur, iyo silicon. Tijaabada hantida farsamada waxaa ka mid ah xoogga jiidista (ugu yaraan 415 MPa), xoogga wax soo saarka (ugu yaraan 205 MPa), iyo cabbiraadda dheereynta sida waafaqsan heerarka ASTM A370. Codsiyada heerkulka hooseeya, tijaabinta saameynta Charpy V-Notch ee ikhtiyaariga ah ee heerkulka la cayimay (heerka ugu yar -29°C) ayaa la samayn karaa si loo xaqiijiyo adkaanta agabka.

Flange kasta oo indho la'aan ah oo muraayad ah ayaa mara xaqiijin cabbir 100% ah iyadoo la adeegsanayo qalab cabbir oo la hagaajiyay. Cabbirrada muhiimka ah ee la baaray waxaa ka mid ah: dhexroorka dibadda (±1.5mm dulqaad), dhexroorka wareegga boolka (±0.8mm), dhexroorka godka boolka iyo booska (±0.5mm), dhumucda (±0.5mm shuruudaha ASME B16.48 kasta), iyo fidsanaanta fool-ka-fool (gudaha 0.2mm ee dusha sare ee shaabadaynta). Fiiro gaar ah ayaa la siiyaa isku-xidhka gacanta baaldiga iyo xaqiijinta nadiifinta si loo helo wareeg sax ah oo u dhexeeya flanges-ka ASME B16.5 ee caadiga ah.

HABKA SOO SAARKA

| 1. Dooro walxo cayriin ah oo asal ah | 2. Jar walxaha ceeriin ah | 3. Kuleylinta kahor |

| 4. Samaynta | 5. Daaweynta kulaylka | 6. Makiinadaha adag |

| 7. Qodista | 8. Mashruuc fiican | 9. Calaamadaynta |

| 10. Kormeerka | 11. Baakad | 12. Bixinta |

Soo bandhigida badeecada

Muuqaallo Codsi oo Kala Duwan: Muuqaalkan Jaantuska-8aad ee Indho-shareerka ah waa aalad badbaado oo caalami ah oo loo isticmaalo warshadaha oo dhan meel kasta oo nidaamyada tuubooyinku u baahan yihiin go'doomin la isku halleyn karo:

- Warshadaha Saliida iyo Warshadaha Kiimikada Baatroolka: Si loo kala saaro fal-galayaasha, tiirarka, beddelayaasha kulaylka, iyo bambooyinka inta lagu jiro dayactirka ama isbeddelka kicinta.

- Soo Saarista/Gudbinta Saliidda & Gaaska: Tuubooyinka dhuumaha, ceelasha, iyo ka hor furayaasha badbaadada cadaadiska (PSVs) si loogu go'doomo ammaan ah inta lagu jiro tijaabinta ama dayactirka.

- Soo saarista Korontada: Qadadka uumiga, nidaamyada biyaha quudinta, iyo khadadka shidaalka si loo kala saaro qaybaha warshadda si dib loogu habeeyo.

- Habaynta Kiimikada iyo Daawooyinka: Si looga hortago wasakhowga iskutallaabta ah ee u dhexeeya dufcadaha ama inta lagu jiro nadiifinta qalabka (CIP/SIP).

- Daaweynta Biyaha & Dhismaha Maraakiibta: Si loo kala sooco bambooyinka, waalka, iyo taangiyada nidaamyada korontada.

Faa'iidooyinka Sahayda iyo Wax-soo-saarka:

- Sameynta Gudaha Guriga oo Dhammaystiran: Waxaan xakameynaa geeddi-socodka oo dhan laga bilaabo soo iibsiga agabka, jarista, farsamaynta, ilaa dhammaystirka, hubinta tayada iyo keenista waqtigii loogu talagalay.

- Khabiirnimada Agabka: Waxaan bixinaa hagitaan ku saabsan xulashada agabka (A515 vs. A516, birta kaarboonka iyo birta aan miridhku lahayn) iyadoo lagu saleynayo xaaladahaaga gaarka ah ee adeegga (heerkulka, cadaadiska, daxalka).

- Awoodda Habaynta: Waxaan soo saari karnaa daahyada muraayadaha ee dhumucdoodu aan caadiga ahayn, oo leh qaabab godad gaar ah, naqshado gacan oo gaar ah, ama agab kale (birta aan daxalka lahayn, birta dahaarka leh) marka la codsado.

- Naqshadeynta Badbaadada-Marka Hore: Alaabooyinkayaga waxaa lagu soo saaray iyadoo maskaxda lagu hayo badbaadada hawlwadeenka, iyadoo leh baaldiyo cad oo adag iyo cabbirro sax ah si loo fududeeyo oo loo maareeyo inta lagu jiro rakibidda iyo wareegga.

- Waxtarka Silsiladda Sahayda Caalamiga ah: Maadaama aan nahay dhoofiye khibrad leh, waxaan xirxirnaa oo diiwaangelinaa shixnadaha si ay u buuxiyaan heerarka caalamiga ah, annagoo hubinayna in qaybahaaga muhiimka u ah badbaadada ay goobta yimaadaan iyagoo diyaar u ah rakibidda. Waxaan bixinnaa xog farsamo oo dhammaystiran iyo taageero si loo fududeeyo is-dhexgalka siman ee hababka dayactirka iyo badbaadadaada.

Qalabka tuubooyinka waa qaybo muhiim u ah nidaamka tuubooyinka, kuwaas oo loo isticmaalo isku xirka, dib u habeynta, leexinta, isbeddelka cabbirka, shaabadeynta ama xakamaynta socodka dareeraha. Waxaa si weyn loogu adeegsadaa meelaha sida dhismaha, warshadaha, tamarta iyo adeegyada degmada.

Hawlaha Muhiimka ah:Waxay qaban kartaa shaqooyin sida isku xirka tuubooyinka, beddelka jihada socodka, kala qaybinta iyo isku darka socodka, hagaajinta dhexroorka tuubooyinka, xidhitaanka tuubooyinka, xakamaynta iyo nidaaminta.

Baaxadda Codsiga:

- Biyo-mareenka dhismaha iyo biyo-mareenka:Xusullada PVC iyo PPR tris ayaa loo isticmaalaa shabakadaha tuubooyinka biyaha.

- Dhuumaha warshadaha:Fiilooyinka birta aan lahayn iyo xusullada birta ah ee dahaarka leh ayaa loo isticmaalaa in lagu qaado warbaahinta kiimikada.

- Gaadiidka tamarta:Tuubooyinka birta ah ee cadaadiska sare leh ayaa loo isticmaalaa dhuumaha saliidda iyo gaaska.

- HVAC (Kuleyliyaha, Hawada, iyo Qaboojiyaha Hawada):Qalabka tuubooyinka naxaasta ah ayaa loo isticmaalaa in lagu xiro dhuumaha qaboojiyaha, iyo kala-goysyada dabacsan ayaa loo isticmaalaa yaraynta gariirka.

- Waraabka Beeraha:Xidhiidhiyayaasha degdega ah waxay sahlaan isu-imaatinka iyo kala-furka nidaamyada waraabka rusheeyaha.

-

ANSI 150LB 1″ 4 inji Alxanka godka SW SS...

-

ASME b16.48 Iibka Warshadda Birta Kaarboonka ah 8 ...

-

Kaarboon Bir ah oo Froged Blind EN1092-1 Flange Blind...

-

bir kaarboon ah oo ah nooca loo yaqaan 'a105' oo ah nooca 'BL flange'

-

ASME B16.48 CL150 CL300 oo ah meel bannaan oo loox ah oo loogu talagalay ...

-

ASME B16.5 BL RF ASTM A182 F316L stee aan miridh lahayn...