QAABKA

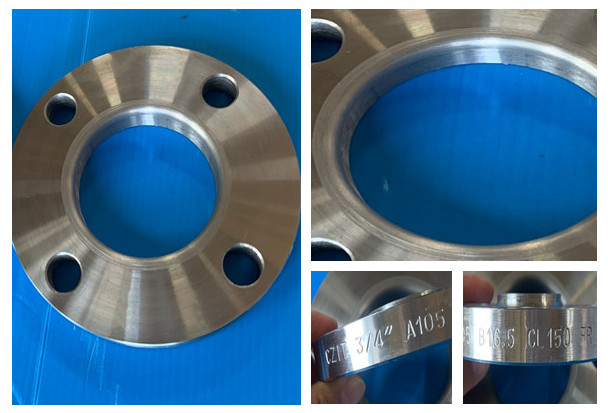

| Magaca Alaabta | Laabta dhabta ah/Fange dabacsan |

| Cabbirka | 1/2"-24" |

| Cadaadis | 150#-2500#,PN0.6-PN400,5K-40K |

| Heerka | ANSI B16.5,EN1092-1, JIS B2220 iwm. |

| Dhamaadka caarada | MSS SP 43, ASME B16.9 |

| Qalab | Bir daxal laheyn:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1,4301, 1.5.14.1,4307. 54Mo iyo iwm. |

| Birta kaarboon:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24 , A515 Gr60, A515 Gr 70 iwm. | |

| Duplex birta aan lahayn:UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 , UNS32760, 1.4462,1.4410,1.4501 iyo iwm. | |

| Birta tuubooyinka:A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 iwm. | |

| Alloy nikel:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H, C22, C-276, Monel400, Alloy20 iwm. | |

| Cr-Mo alloy:A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, iwm. | |

| Codsiga | Warshadaha Batroolka, warshadaha duulista iyo hawada sare, warshadaha dawooyinka, qiiqa gaasta, warshada tamarta, dhismaha markabka, daaweynta biyaha, iwm. |

| Faa'iidooyinka | kayd diyaar ah, waqti dhalista degdega ah; la heli karo dhammaan cabbirrada, la habeeyey, tayo sare leh |

HEERARKA MEEJINTA

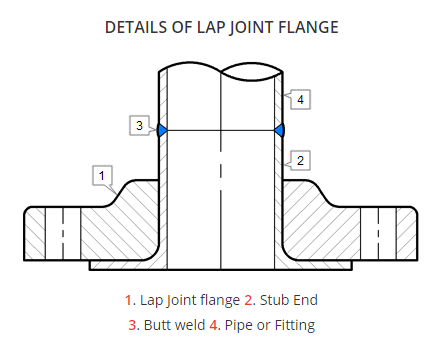

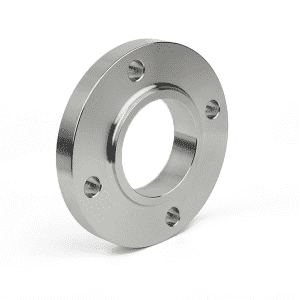

CALANKA WADAJIRKA LAP

Flange-la-goyska dhabta ah wuxuu u baahan yahay laba qaybood oo tuubooyin ah dhinac kasta oo ka mid ah xidhiidhka flanged, cidhif caarad ah iyo garab dabac ah.Flange dhabarka dabacsan wuxuu ku habboon yahay dhexroorka dibadda ee dhamaadka saxarada, kaas oo dabada ku alxan tuubada.Flange dhabarka laguma alxan tuubada, waana la rogi karaa, taas oo si gaar ah faa'iido u leh marka ay lagama maarmaan tahay in la jiheeyo flanges xilliga kacsiga.

Sidoo kale, maadaama garabka dhabarku uusan la xiriirin dareeraha habka, waxay ka samaysan kartaa walxo aan u adkaysan karin.Tusaale ahaan, haddii geeddi-socodku yahay mid daxalaystay oo u baahan in tuubadu ay noqoto bir aan bir lahayn, sida ku jirta ASTM A312 TP316L, markaa dhammaadka caarada waa in sidoo kale laga sameeyaa SS 316L;si kastaba ha ahaatee, flange dhabarka waxaa laga samayn karaa ASTM A105 ka jaban.

Habkan isku xidhiddu maaha mid u adag sida flange luqunta alxanka laakiin wuu ka sarreeyaa marooqsan, alxanka godka, iyo silbashada xidhiidhka;si kastaba ha ahaatee, waa qaali in la fuliyo, sababtoo ah waxay u baahan tahay alxanka dabada oo buuxa waxayna u baahan tahay laba qaybood.

DHAMMAAN DHAMMAAN

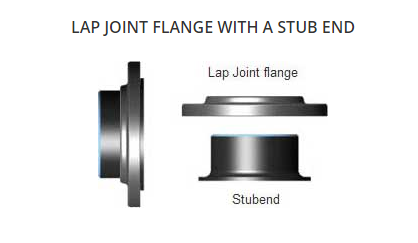

Dhamaadka Stub-ka had iyo jeer waxaa loo isticmaali doonaa Flange Lap Joint flange, sida garab garab.

Isku xirka flange-gan waxaa lagu dabaqaa, cadaadis hooseeya iyo codsiyada aan muhiimka ahayn, waana hab jaban oo flanging ah.

Nidaamka dhuumaha birta ah, tusaale ahaan, flange birta kaarboon ayaa lagu dabaqi karaa, sababtoo ah lama xiriirin alaabta tuubada.

Stub Ends ayaa laga heli karaa ku dhawaad dhammaan dhexrooryada tuubooyinka.Cabbirrada iyo dulqaadka cabbirka ayaa lagu qeexay heerka ASME B.16.9.Daxalka u adkaysta miisaanka khafiifka ah ee loo yaqaan 'Stub Ends' ayaa lagu qeexay MSS SP43.

KA FAA'IIDEYSAN KARAA CALANKA WADAJIRKA LAP

- Xorriyadda in lagu wareego agagaarka tuubada waxay sahlaysa xayndaabka godadka flange ee iska soo horjeeda.

- Xidhiidh la'aanta dareeraha tuubada inta badan waxay ogolaataa isticmaalka birta kaarboonka ee jaban oo leh tuubo u adkaysata daxalka.

- Nidaamyada burbura ama si degdeg ah u daxalooda, garbaha ayaa laga yaabaa in la badbaadiyo si dib loogu isticmaalo.

SHOW FAAHFAAHINTA Alaabooyinka

1. Wajiga

wejiga fidsan, Radius waa kan ugu muhiimsan

2. Hub la'aan ama hub la'aan

3.Face dhammayn

Dhammaystirka wejiga flange waxaa lagu qiyaasaa sida Celceliska Dhererka Roughness (AARH).Dhammaadka waxaa lagu go'aamiyaa heerka la isticmaalo.Tusaale ahaan, ANSI B16.5 waxay qeexaysaa dhamaystirka wejiga inta u dhaxaysa 125AARH-500AARH (3.2Ra ilaa 12.5Ra).Dhammaystirka kale ayaa lagu heli karaa codsi, tusaale ahaan 1.6 Ra max,1.6/3.2 Ra, 3.2/6.3Ra ama 6.3/12.5Ra.Qiyaasta 3.2/6.3Ra ayaa ah inta badan.

SAMEYNTA IYO BAA-QABSIGA

• Lakab kastaa wuxuu isticmaalaa filim caag ah si uu u ilaaliyo dusha sare

• Dhammaan birta aan-kala-sooca lahayn waxaa ka buuxa kiis alwaax ah.Xajmiga kaarboonka ee cabbirka ka weyn waxaa lagu soo raray alwaax alwaax ah.Ama waxaa la habeyn karaa xirxiro.

• Calaamadda dhoofintu waxay samayn kartaa marka la codsado

• Calaamadaha alaabta waa la xarri karaa ama la daabici karaa.OEM waa la aqbalay

KORMEERKA

• Tijaabada UT

• Tijaabada PT

• Tijaabada MT

• Imtixaanka cabbirka

Kahor dhalmada ka hor, kooxdayada QC waxay qabanqaabin doonaan baaritaanka NDT iyo cabbirka cabbirka. Sidoo kale aqbal TPI (baaritaan dhinaca saddexaad ah).

HABKA SOO SAARKA

| 1. Dooro alaabta ceeriin ee dhabta ah | 2. Iska jar alaabta ceeriin | 3. Kuleyl ka hor |

| 4. Been abuurasho | 5. Daaweynta kulaylka | 6. Machining qalafsan |

| 7. qodista | 8. Maching fiican | 9. Calaamadaynta |

| 10. Kormeer | 11. Baakad | 12. Gaadhsiin |

-

meel bannaan oo bannaan A515 gr 60 sawir 8 muuqaal ah...

-

A105 150lb Dn150 warqad alxanka kaarboon ah oo ku saabsan f ...

-

WN ANSI B16.36 orifice alxanka qoorta flange leh ja...

-

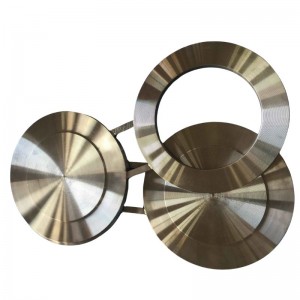

ASME b16.48 Warshada iibka kaarboonka sawirka 8 ...

-

ASME B16.5 BL RF ASTM A182 F316L Stee aan lahayn

-

ANSI DIN Been Abuur Fasalka 150 Birta Aan Lahayn o...