QAABKA

| Magaca Alaabta | Laabta dhabta ah/Fange dabacsan |

| Cabbirka | 1/2"-24" |

| Cadaadis | 150#-2500#,PN0.6-PN400,5K-40K |

| Heerka | ANSI B16.5,EN1092-1, JIS B2220 iwm. |

| Dhamaadka caarada | MSS SP 43, ASME B16.9 |

| Qalab | Bir daxal laheyn:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1,4301, 1.5.14.1,4307. 54Mo iyo iwm. |

| Birta kaarboon:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24 , A515 Gr60, A515 Gr 70 iwm. | |

| Duplex birta aan lahayn:UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 , UNS32760, 1.4462,1.4410,1.4501 iyo iwm. | |

| Birta tuubooyinka:A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 iwm. | |

| Alloy nikel:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H, C22, C-276, Monel400, Alloy20 iwm. | |

| Cr-Mo alloy:A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, iwm. | |

| Codsiga | Warshadaha Batroolka, warshadaha duulista iyo hawada sare, warshadaha dawooyinka, qiiqa gaasta, warshada tamarta, dhismaha markabka, daaweynta biyaha, iwm. |

| Faa'iidooyinka | kayd diyaar ah, waqti dhalista degdega ah; la heli karo dhammaan cabbirrada, la habeeyey, tayo sare leh |

HEERARKA MEEJINTA

SHOW FAAHFAAHINTA Alaabooyinka

1. Wajiga

Waxaa kor loo qaadi karaa wejiga (RF), waji buuxa (FF), Isku-dhafka giraanta (RTJ), Groove, Carrabka, ama la habeyn karo.

2.Bevel dhamaadka sida ku cad ANSI B16.25

3.CNC ganaax dhameeyay.

Dhamaystirka wejiga: Dhammaadka wejiga flange waxaa lagu qiyaasaa celceliska Roughness Height (AARH).Dhammaadka waxaa lagu go'aamiyaa heerka la isticmaalo.Tusaale ahaan, ANSI B16.5 waxay qeexaysaa dhamaystirka wejiga inta u dhaxaysa 125AARH-500AARH (3.2Ra ilaa 12.5Ra).Dhammaystirka kale ayaa lagu heli karaa codsi, tusaale ahaan 1.6 Ra max,1.6/3.2 Ra, 3.2/6.3Ra ama 6.3/12.5Ra.Qiyaasta 3.2/6.3Ra ayaa ah inta badan.

SAMEYNTA IYO BAA-QABSIGA

• Lakab kastaa wuxuu isticmaalaa filim caag ah si uu u ilaaliyo dusha sare

• Dhammaan birta aan-kala-sooca lahayn waxaa ka buuxa kiis alwaax ah.Xajmiga kaarboonka ee cabbirka ka weyn waxaa lagu soo raray alwaax alwaax ah.Ama waxaa la habeyn karaa xirxiro.

• Calaamadda dhoofintu waxay samayn kartaa marka la codsado

• Calaamadaha alaabta waa la xarri karaa ama la daabici karaa.OEM waa la aqbalay

KORMEERKA

• Tijaabada UT

• Tijaabada PT

• Tijaabada MT

• Imtixaanka cabbirka

Kahor dhalmada ka hor, kooxdayada QC waxay qabanqaabin doonaan baaritaanka NDT iyo cabbirka cabbirka. Sidoo kale aqbal TPI (baaritaan dhinaca saddexaad ah).

HABKA SOO SAARKA

| 1. Dooro alaabta ceeriin ee dhabta ah | 2. Iska jar alaabta ceeriin | 3. Kuleyl ka hor |

| 4. Been abuurasho | 5. Daaweynta kulaylka | 6. Machining qalafsan |

| 7. qodista | 8. Maching fiican | 9. Calaamadaynta |

| 10. Kormeer | 11. Baakad | 12. Gaadhsiin |

Kiiska iskaashiga

Mashruuc ka socda Turkiga, flanges ayaa loo isticmaalaa dhuumaha gaaska dabiiciga ah.Dhammaan garabyadaas waxaa ansixiyay TUV.

XAASHIDA XOGTA FLANGE

1.Cabirka Flange iyo dulqaadku waa inay ahaadaan si waafaqsan ASME B16.5.

2. Flanges waa in lagu soo saaraa been abuur.

3. Qalabku waa inay waafaqsan yihiin heerarka ASTM A105, ASTM A694 F65 iyo ASTM A694 F70.

4. ASTM A694 F65 iyo ASTM A694 F70 garabyada waa in la demiyo oo la dabciyaa.

5. Shahaadooyinka tijaabada agabka iyo warbixinada daaweynta kulaylka waa in loo diyaariyaa baaritaanada TPI.

6. Garaafka WN waa in ay la socdaan cidhifyada bevel acc.ilaa ASME B16.25.

7. Qalabka kiimikada iyo qiimaha tijaabada farsamada (saamaynta, wax-soo-saarka, xajinta iwm.) waa inay ahaataa mid waafaqsan heerarka la xidhiidha.

8. Dhammaan sagxadaha waa in lagu farsameeyaa oo lagu damiyaa saliid hufan si looga hortago daxalka.

9. Calaamadaynta waa in ay ku jirtaa macluumaadka soo socda.

Dhexroorka (Ex. 6")

Heerka cadaadiska (Ex. 150 LB)

• Darajada Alaabta (Ex. ASTM A 105)

• Dhumucdiisuna waxay tahay 4,78 mm.

• Kulaylka Maya (Ex. 138413)

• Heerka wax soo saarka (ASME B16.5)

10. Alaabtu waa inay ka nadiif ahaadaan ciladaha dusha sare iyo dildilaaca.Dayactirka alxanka waa mamnuuc.

11. Dhammaan garabyadu waa inay kor u qaadaan wejiga (RF) oo leh dusha daboolan.Oogada daboolista waa inay ahaataa Ra 3,2 - 6,3 µm (125 - 250 mic. inc) acc.ilaa ASME B46.1.

12. Alaabta waa in la xidho si looga hortago waxyeelada mashiinada, iyo xidhidhiyaha sagxadaha.

13. Dhammaan cabbiradu waa inay ahaadaan dulqaad (+) togan.Dulqaadka laga jaray waa mamnuuc.

14. Gawaarida caleenta waa in la sameeyaa acc.ilaa ASME B16.25.

15. Habka wax soo saarka waxaa hubin doona TPI wakhti kasta.

16. TPI waxay ka qaadi kartaa muunado walxo kasta oo ah muunada tijaabada kiimikaad/farsamo.

17. Warbixinta kormeerka ee soo socota waa in ay dib u eegto TPI.

| Shayga | Cabbirka (Inji) | Heerka Cadaadiska | CS | Qalab | WT (mm) | Goobta | Qty. |

| SORF | 12 | 150LB | 20 | A105 | - | CALANKA taangiga | 48 |

| SORF | 8 | 150LB | 20 | A105 | - | CALANKA taangiga | 32 |

| SORF | 3 | 150LB | 20 | A105 | - | CALANKA taangiga | 32 |

| Flange, Qoorta alxanka | 24 | 150LB | 20 | A105 | 14 | CALANKA taangiga | 2 |

| Flange, Qoorta alxanka | 24 | 150LB | 20 | A105 | 5.54 | CALANKA taangiga | 4 |

| SORF | 20 | 150LB | 20 | A105 | - | CALANKA taangiga | 6 |

| Flange, Qoorta alxanka | 24 | 150LB | 20 | A105 | 5.54 | CALANKA taangiga | 8 |

| Flange, Qoorta alxanka | 24 | 150LB | 20 | A105 | 14 | CALANKA taangiga | 8 |

| Flange, Qoorta alxanka | 24 | 150LB | 20 | A105 | 16 | CALANKA taangiga | 8 |

| SORF | 3 | 150LB | 20 | A105 | - | CALANKA taangiga | 24 |

| SORF | 20 | 150LB | 20 | A105 | - | CALANKA taangiga | 6 |

| Flange, Qoorta alxanka | 24 | 150LB | 20 | A105 | 5.54 | CALANKA taangiga | 8 |

| Flange, Qoorta alxanka | 24 | 150LB | 20 | A105 | 14 | CALANKA taangiga | 16 |

| Shayga | Cabbirka (Inji) | Heerka Cadaadiska | CS | Qalab | WT (mm) | Goobta | Qty. |

| Flange, Qoorta alxanka | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Qoorta alxanka | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Qoorta alxanka | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Qoorta alxanka | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Qoorta alxanka | 12 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Qoorta alxanka | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Qoorta alxanka | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Qoorta alxanka | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Qoorta alxanka | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Qoorta alxanka | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Qoorta alxanka | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Qoorta alxanka | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Qoorta alxanka | 12 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Qoorta alxanka | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Qoorta alxanka | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Qoorta alxanka | 10 | 300LB | 51 | ASTM A694 F65 | 4.78 | PSB1 | 2 |

| Flange, Qoorta alxanka | 6 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flange, Qoorta alxanka | 4 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flange, Qoorta alxanka | 18 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flange, Qoorta alxanka | 8 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flange, Qoorta alxanka | 8 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

FAQ

1. Waa maxay noocyada kala duwan ee xirmooyinka tuubooyinka birta ah?

Jawaab: Qalabka birta ah ee ku rakiban waxaa ka mid ah xirmooyinka tuubooyinka alxanka dabada, xirmooyinka tuubooyinka alxanka, xirmooyinka tuubooyinka dunta leh, flanges, valves iyo noocyo kale.

2. Waa maxay faraqa u dhexeeya birta 304 iyo 316 xirmooyinka tuubooyinka birta?

A: 304 birta daxalka ah ayaa ku habboon codsiyada badankood waxayna leedahay iska caabin daxalka oo aad u fiican.316 birta aan daxalka lahayn, dhanka kale, waxay leedahay iska caabin daxalka ka wanaagsan ee bay'adaha aadka u daxalka ah waxayna ku habboon tahay codsiyada badda iyo kiimikada.

3. Waa maxay faa'iidooyinka isticmaalka tuubooyinka dabada ka samaysan ee been abuurka ah?

J: Qalabyada alxanka dabada ee la been abuuray waxay bixiyaan xoog la xoojiyey, isku halaynta, iyo xidhiidhada bilaa daadsan.Waxay bixiyaan iska caabin saameyn aad u wanaagsan waxaana loo door bidaa cadaadiska sare iyo codsiyada heerkulka sare.

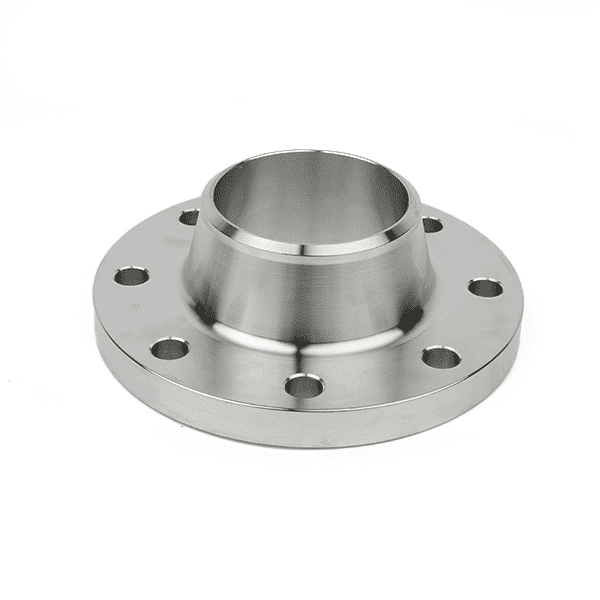

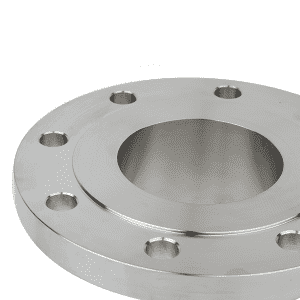

4. Waa maxay alxanka dabada?

Jawaab: Flange alxanka dabada waa flange tubbada oo leh xuddunta dheer ee duuban oo lagu alxanayo tuubada.Waxay ku siinaysaa si habsami leh uga gudubka tuubada una gudubta flange leh xoog iyo daacadnimo aad u fiican.

5. Waa kuwee darajada birta ah ee sida caadiga ah loo isticmaalo xirmooyinka tuubooyinka?

J: Fasalada aan birta lahayn ee 304, 316, 304L, 316L iyo 317 waxaa caadi ahaan loo adeegsadaa xirmooyinka tuubooyinka sababtoo ah caabbinta daxalka ee aadka u fiican, adkeysigooda iyo badiyaashooda.

6. Xirmooyinka tuubooyinka birta ah ma loo isticmaali karaa codsiyada heerkulka sare?

Jawaab: Haa, qalabka birta ah ee aan fiicnayn waxay ku habboon yihiin codsiyada heerkulka sare.Si kastaba ha ahaatee, darajada birta aan la isticmaalin waa in si taxadar leh loo doortaa iyadoo lagu saleynayo shuruudaha heerkulka gaarka ah ee codsiga.

7. Tuubbooyinka birta-la'aanta ah miyay ku habboon yihiin warshadaha cuntada iyo cabitaanka?

Jawaab: Haa, xirmooyinka tuubooyinka birta aan-ka-soo-baxa ayaa si weyn loogu isticmaalaa warshadaha cuntada iyo cabitaanka sababtoo ah nadaafaddooda, caabbinta daxalka, iyo dayactirka fudud.

8. Waa maxay faraqa u dhexeeya alxanka godka iyo alxanka dabada?

Jawaab: Xirmooyinka tuubbada alxanka leh ee godadku waxay geliyaan tuubada godka ka dibna waxay sameeyaan alxanka fillet si ay ugu xidhaan tuubada.Qalabka alxanka dabada, dhanka kale, waxay u baahan yihiin in cidhifyada tuubada la jeexjeexo ka dibna la alxanayo.

9. Ma dib loo warshadayn karaa tuubooyinka birta aan-dhalatada lahayn?

J: Haa, xidhmooyinka tuubooyinka birta ah ee birta ah ayaa aad dib loo warshadayn karaa.Birta aan lahayni waa shay waara oo dib loo warshadayn karo oo dib loo isticmaali karo iyada oo aan la lumin hantideeda ama tayadeeda.

10. Waa maxay faa'iidooyinka isticmaalka tuubooyinka birta aan la taaban karin marka la barbar dhigo alaabta kale?

A: Qalabka birta ah ee birta ah ayaa bixiya faa'iidooyin badan, sida caabbinta daxalka oo aad u fiican, xoog sare, adkeysi iyo sifooyinka nadaafadda.Waxay leeyihiin dayactir hooseeya, waxay leeyihiin cimri dherer waxayna leeyihiin muuqaal nadiif ah oo qurux badan.

SHOW FAAHFAAHINTA Alaabooyinka

1. Wajiga

Waxaa kor loo qaadi karaa wejiga (RF), waji buuxa (FF), Isku-dhafka giraanta (RTJ), Groove, Carrabka, ama la habeyn karo.

2.Bevel dhamaadka sida ku cad ANSI B16.25

3.CNC ganaax dhameeyay.

Dhamaystirka wejiga: Dhammaadka wejiga flange waxaa lagu qiyaasaa celceliska Roughness Height (AARH).Dhammaadka waxaa lagu go'aamiyaa heerka la isticmaalo.Tusaale ahaan, ANSI B16.5 waxay qeexaysaa dhamaystirka wejiga inta u dhaxaysa 125AARH-500AARH (3.2Ra ilaa 12.5Ra).Dhammaystirka kale ayaa lagu heli karaa codsi, tusaale ahaan 1.6 Ra max,1.6/3.2 Ra, 3.2/6.3Ra ama 6.3/12.5Ra.Qiyaasta 3.2/6.3Ra ayaa ah inta badan.

SAMEYNTA IYO BAA-QABSIGA

• Lakab kastaa wuxuu isticmaalaa filim caag ah si uu u ilaaliyo dusha sare

• Dhammaan birta aan-kala-sooca lahayn waxaa ka buuxa kiis alwaax ah.Xajmiga kaarboonka ee cabbirka ka weyn waxaa lagu soo raray alwaax alwaax ah.Ama waxaa la habeyn karaa xirxiro.

• Calaamadda dhoofintu waxay samayn kartaa marka la codsado

• Calaamadaha alaabta waa la xarri karaa ama la daabici karaa.OEM waa la aqbalay

KORMEERKA

• Tijaabada UT

• Tijaabada PT

• Tijaabada MT

• Imtixaanka cabbirka

Kahor dhalmada ka hor, kooxdayada QC waxay qabanqaabin doonaan baaritaanka NDT iyo cabbirka cabbirka. Sidoo kale aqbal TPI (baaritaan dhinaca saddexaad ah).

HABKA SOO SAARKA

| 1. Dooro alaabta ceeriin ee dhabta ah | 2. Iska jar alaabta ceeriin | 3. Kuleyl ka hor |

| 4. Been abuurasho | 5. Daaweynta kulaylka | 6. Machining qalafsan |

| 7. qodista | 8. Maching fiican | 9. Calaamadaynta |

| 10. Kormeer | 11. Baakad | 12. Gaadhsiin |

Kiiska iskaashiga

Mashruuc ka socda Turkiga, flanges ayaa loo isticmaalaa dhuumaha gaaska dabiiciga ah.Dhammaan garabyadaas waxaa ansixiyay TUV.

XAASHIDA XOGTA FLANGE

1. Cabirka Flange iyo dulqaadku waa in ay ahaadaan si waafaqsan ASME B16.5.

2. Flanges waa in lagu soo saaraa been abuur.

3. Qalabku waa inay waafaqsan yihiin heerarka ASTM A105, ASTM A694 F65 iyo ASTM A694 F70.

4. ASTM A694 F65 iyo ASTM A694 F70 garabyada waa in la demiyo oo la dabciyaa.

5. Shahaadooyinka tijaabada agabka iyo warbixinada daaweynta kulaylka waa in loo diyaariyaa baaritaanada TPI.

6. Garaafka WN waa in ay la socdaan cidhifyada bevel acc.ilaa ASME B16.25.

7. Qalabka kiimikada iyo qiimaha tijaabada farsamada (saamaynta, wax-soo-saarka, xajinta iwm.) waa inay ahaataa mid waafaqsan heerarka la xidhiidha.

8. Dhammaan sagxadaha waa in lagu farsameeyaa oo lagu damiyaa saliid hufan si looga hortago daxalka.

9. Calaamadaynta waa in ay ku jirtaa macluumaadka soo socda.

Dhexroorka (Ex. 6")

Heerka cadaadiska (Ex. 150 LB)

• Darajada Alaabta (Ex. ASTM A 105)

• Dhumucdiisuna waxay tahay 4,78 mm.

• Kulaylka Maya (Ex. 138413)

• Heerka wax soo saarka (ASME B16.5)

10. Alaabtu waa inay ka nadiif ahaadaan ciladaha dusha sare iyo dildilaaca.Dayactirka alxanka waa mamnuuc.

11. Dhammaan garabyadu waa inay kor u qaadaan wejiga (RF) oo leh dusha daboolan.Oogada daboolista waa inay ahaataa Ra 3,2 - 6,3 µm (125 - 250 mic. inc) acc.ilaa ASME B46.1.

12. Alaabta waa in la xidho si looga hortago waxyeelada mashiinada, iyo xidhidhiyaha sagxadaha.

13. Dhammaan cabbiradu waa inay ahaadaan dulqaad (+) togan.Dulqaadka laga jaray waa mamnuuc.

14. Gawaarida caleenta waa in la sameeyaa acc.ilaa ASME B16.25.

15. Habka wax soo saarka waxaa hubin doona TPI wakhti kasta.

16. TPI waxay ka qaadi kartaa muunado walxo kasta oo ah muunada tijaabada kiimikaad/farsamo.

17. Warbixinta kormeerka ee soo socota waa in ay dib u eegto TPI.

| Shayga | Cabbirka (Inji) | Heerka Cadaadiska | CS | Qalab | WT (mm) | Goobta | Qty. |

| SORF | 12 | 150LB | 20 | A105 | - | CALANKA taangiga | 48 |

| SORF | 8 | 150LB | 20 | A105 | - | CALANKA taangiga | 32 |

| SORF | 3 | 150LB | 20 | A105 | - | CALANKA taangiga | 32 |

| Flange, Qoorta alxanka | 24 | 150LB | 20 | A105 | 14 | CALANKA taangiga | 2 |

| Flange, Qoorta alxanka | 24 | 150LB | 20 | A105 | 5.54 | CALANKA taangiga | 4 |

| SORF | 20 | 150LB | 20 | A105 | - | CALANKA taangiga | 6 |

| Flange, Qoorta alxanka | 24 | 150LB | 20 | A105 | 5.54 | CALANKA taangiga | 8 |

| Flange, Qoorta alxanka | 24 | 150LB | 20 | A105 | 14 | CALANKA taangiga | 8 |

| Flange, Qoorta alxanka | 24 | 150LB | 20 | A105 | 16 | CALANKA taangiga | 8 |

| SORF | 3 | 150LB | 20 | A105 | - | CALANKA taangiga | 24 |

| SORF | 20 | 150LB | 20 | A105 | - | CALANKA taangiga | 6 |

| Flange, Qoorta alxanka | 24 | 150LB | 20 | A105 | 5.54 | CALANKA taangiga | 8 |

| Flange, Qoorta alxanka | 24 | 150LB | 20 | A105 | 14 | CALANKA taangiga | 16 |

| Shayga | Cabbirka (Inji) | Heerka Cadaadiska | CS | Qalab | WT (mm) | Goobta | Qty. |

| Flange, Qoorta alxanka | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Qoorta alxanka | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Qoorta alxanka | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Qoorta alxanka | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Qoorta alxanka | 12 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Qoorta alxanka | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Qoorta alxanka | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Qoorta alxanka | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Qoorta alxanka | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Qoorta alxanka | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Qoorta alxanka | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Qoorta alxanka | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Qoorta alxanka | 12 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Qoorta alxanka | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Qoorta alxanka | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Qoorta alxanka | 10 | 300LB | 51 | ASTM A694 F65 | 4.78 | PSB1 | 2 |

| Flange, Qoorta alxanka | 6 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flange, Qoorta alxanka | 4 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flange, Qoorta alxanka | 18 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flange, Qoorta alxanka | 8 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flange, Qoorta alxanka | 8 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

-

Alxanka birta kor loo qaaday flange EN1092-1 type0 ...

-

WN ANSI B16.36 orifice alxanka qoorta flange leh ja...

-

Socket alxanka flange A105 kaarboon birta SW RTJ 3/4 ...

-

Isku dhufashada BSP DIN PN 10/16 birta kaarboon A105 flange

-

meel bannaan oo bannaan A515 gr 60 sawir 8 muuqaal ah...

-

ASME B16.48 CL150 CL300 Paddle spacer plank fla...