QEEXIDDA

| Magaca Badeecada | Kala-goyska dhabta/flange dabacsan |

| Cabbirka | 1/2"-24" |

| Cadaadis | 150#-2500#,PN0.6-PN400,5K-40K |

| Heerka Caadiga ah | ANSI B16.5,EN1092-1, JIS B2220 iwm. |

| Dhamaadka stub | MSS SP 43, ASME B16.9 |

| Alaab | Bir aan daxal lahayn:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571,1.4541, 254Mo iyo iwm. |

| Bir kaarboon ah:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24, A515 Gr60, A515 Gr 70 iwm. | |

| Bir aan daxal lahayn oo laba jibbaaran:UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462,1.4410,1.4501 iyo iwm. | |

| Birta dhuumaha:A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 iwm. | |

| Daawaha Nikkel:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H, C22, C-276, Monel400, Alloy20 iwm. | |

| Daawaha Cr-Mo:A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, iwm. | |

| Codsiga | Warshadaha kiimikada batroolka; warshadaha duulista iyo hawada sare; warshadaha dawooyinka; qiiqa gaaska; warshadda korontada; dhismaha maraakiibta; daaweynta biyaha, iwm. |

| Faa'iidooyinka | kayd diyaar ah, waqti gaarsiin degdeg ah; laga heli karo cabbirro kasta, la habeeyey; tayo sare leh |

HEERARKA CABBIRKA

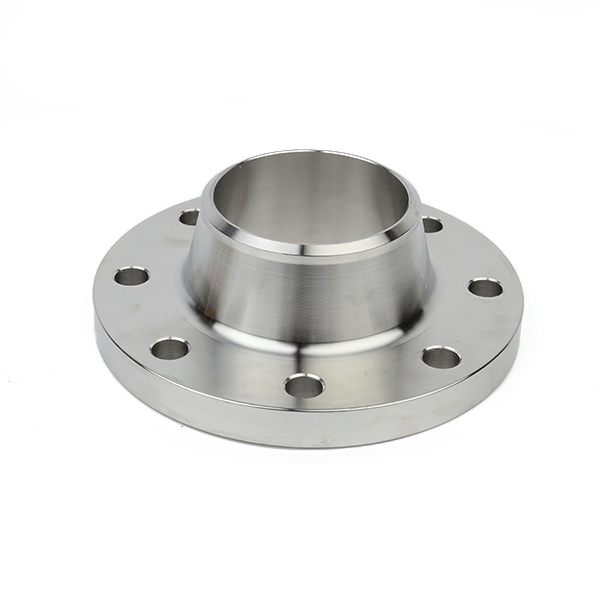

BANDHIG FAAHFAAHINTA ALAABADA

1. Wajiga

Waxaa kor loo qaadi karaa wejiga (RF), wejiga oo dhan (FF), kala-goyska giraanta (RTJ), jeexdin, carrab, ama loo habeyn karaa.

2. Dhammaadka Bevel sida waafaqsan ANSI B16.25

3.CNC si fiican ayaa loo dhammeeyay.

Dhammaadka wejiga: Dhammaadka wejiga flange-ka waxaa lagu cabbiraa Dhererka Xisaabeed ee Celceliska Qalafsan (AARH). Dhammaadka waxaa lagu go'aamiyaa heerka la isticmaalay. Tusaale ahaan, ANSI B16.5 wuxuu qeexayaa dhammaadka wejiga ee u dhexeeya 125AARH-500AARH (3.2Ra ilaa 12.5Ra). Dhammaadka kale waxaa laga heli karaa codsi ahaan, tusaale ahaan 1.6 Ra max, 1.6/3.2 Ra, 3.2/6.3Ra ama 6.3/12.5Ra. Kala duwanaanshaha 3.2/6.3Ra ayaa ugu badan.

CALAAMADAHA IYO BAAKAD-QAADKA

• Lakab kasta wuxuu isticmaalaa filim balaastig ah si uu u ilaaliyo dusha sare

• Dhammaan birta aan miridhku lahayn waxaa lagu buuxiyaa kiis alwaax ah. Haddii aad rabto inaad kaarboonka kaarboonka ah cabbir weyn ku darto baaldi alwaax ah. Ama waxaa lagu beddeli karaa baakad.

• Calaamadda dhoofinta ayaa la samayn karaa marka la codsado

• Calaamadaha alaabta waa la xarri karaa ama la daabacan karaa. OEM waa la aqbalayaa.

KORMEER

• Imtixaanka UT

• Baaritaanka PT

• Baaritaanka MT

• Tijaabada cabbirka

Kahor keenista, kooxdayada QC waxay diyaarin doontaa baaritaanka NDT iyo kormeerka cabbirka. Sidoo kale waxay aqbali doontaa TPI (kormeerka dhinac saddexaad).

HABKA SOO SAARKA

| 1. Dooro walxo cayriin ah oo asal ah | 2. Jar walxaha ceeriin ah | 3. Kuleylinta kahor |

| 4. Samaynta | 5. Daaweynta kulaylka | 6. Makiinadaha adag |

| 7. Qodista | 8. Mashruuc fiican | 9. Calaamadaynta |

| 10. Kormeerka | 11. Baakad | 12. Bixinta |

Kiiska Iskaashi

Mashruuc ka socda Turkiga, flanges-ka waxaa loo isticmaalaa dhuumaha gaaska dabiiciga ah. Dhammaan flanges-kaas waxaa ansixisay TUV.

XAASHIDA XOGTA FLANGE

1Cabbirka iyo dulqaadka flange-ka waa inay waafaqsanaadaan ASME B16.5.

2. Flanges-ka waxaa lagu soo saari doonaa foorno.

3. Alaabtu waa inay waafaqsanaato heerarka ASTM A105, ASTM A694 F65 iyo ASTM A694 F70.

4. Flanges-ka ASTM A694 F65 iyo ASTM A694 F70 waa in la damiyaa oo la qaboojiyaa.

5. Shahaadooyinka tijaabada agabka iyo warbixinnada daaweynta kulaylka waa in loo diyaariyaa kormeerka TPI.

6. Flanges-ka WN waa inay la socdaan darafyada bevel ee la jaanqaadaya ASME B16.25.

7. Qiimaha tijaabada kiimikada iyo farsamada ee walxaha (saamaynta, wax-soo-saarka, jiidista iwm.) waa inay ahaadaan kuwo waafaqsan heerarka la xiriira.

8. Dhammaan dusha sare waa in lagu farsameeyaa oo lagu rinjiyeeyaa saliid hufan si looga hortago miridhku.

9. Calaamadayntu waa inay ku jirtaa macluumaadka soo socda,

• Dhexroorka (dhammaad. 6")

• Heerka cadaadiska (dhammaad ahaan 150 LB)

• Heerka Agabka (tusaale ahaan ASTM A 105)

• Dhumucda derbiga (dhammaad ahaan 4,78 mm)

• Lambarka Kulaylka (dhammaad 138413)

• Heerka wax soo saarka (ASME B16.5)

10. Alaabtu waa inay ka xorowdaa wax cillado iyo dildilaac ah oo dusha sare ah. Dayactirka alxanka waa mamnuuc.

11. Dhammaan flanges-ka waa in kor loo qaadaa wejiga (RF) oo leh dusha shaabadaysan. Dusha shaabadaysan waa inay noqotaa Ra 3,2 – 6,3 µm (125 – 250 mic. oo ay ku jirto) oo la jaanqaadaya ASME B46.1.

12. Agabka waa in la xidhaa si looga hortago waxyeelada soo gaarta mishiinnada, iyo xidhitaanka dusha sare.

13. Dhammaan cabbiradu waa inay ahaadaan kuwo togan (+). Marka laga reebo dulqaadka waa mamnuuc.

14. Qalabka laalaabka ee flange-ka waa in loo habeeyaa ASME B16.25.

15. Habka wax soo saarka waxaa hubin doona TPI wakhti kasta.

16. TPI waxay ka qaadi kartaa muunado walxo kasta oo loogu talagalay muunadda tijaabada kiimikada/farsamada.

17. Warbixinta kormeerka soo socota waxaa dib u eegi doona TPI.

| Shay | Cabbirka (Inji) | Fasalka Cadaadiska | CS | Alaab | WT (mm) | Goobta | Tirada. |

| SORF | 12 | 150LB | 20 | A105 | - | TANGYADA FLANGES | 48 |

| SORF | 8 | 150LB | 20 | A105 | - | TANGYADA FLANGES | 32 |

| SORF | 3 | 150LB | 20 | A105 | - | TANGYADA FLANGES | 32 |

| Flange, Luqunta Alxanka | 24 | 150LB | 20 | A105 | 14 | TANGYADA FLANGES | 2 |

| Flange, Luqunta Alxanka | 24 | 150LB | 20 | A105 | 5.54 | TANGYADA FLANGES | 4 |

| SORF | 20 | 150LB | 20 | A105 | - | TANGYADA FLANGES | 6 |

| Flange, Luqunta Alxanka | 24 | 150LB | 20 | A105 | 5.54 | TANGYADA FLANGES | 8 |

| Flange, Luqunta Alxanka | 24 | 150LB | 20 | A105 | 14 | TANGYADA FLANGES | 8 |

| Flange, Luqunta Alxanka | 24 | 150LB | 20 | A105 | 16 | TANGYADA FLANGES | 8 |

| SORF | 3 | 150LB | 20 | A105 | - | TANGYADA FLANGES | 24 |

| SORF | 20 | 150LB | 20 | A105 | - | TANGYADA FLANGES | 6 |

| Flange, Luqunta Alxanka | 24 | 150LB | 20 | A105 | 5.54 | TANGYADA FLANGES | 8 |

| Flange, Luqunta Alxanka | 24 | 150LB | 20 | A105 | 14 | TANGYADA FLANGES | 16 |

| Shay | Cabbirka (Inji) | Fasalka Cadaadiska | CS | Alaab | WT (mm) | Goobta | Tirada. |

| Flange, Luqunta Alxanka | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Luqunta Alxanka | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Luqunta Alxanka | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Luqunta Alxanka | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Luqunta Alxanka | 12 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Luqunta Alxanka | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Luqunta Alxanka | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Luqunta Alxanka | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Luqunta Alxanka | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Luqunta Alxanka | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Luqunta Alxanka | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Luqunta Alxanka | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Luqunta Alxanka | 12 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Luqunta Alxanka | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Luqunta Alxanka | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Luqunta Alxanka | 10 | 300LB | 51 | ASTM A694 F65 | 4.78 | PSB1 | 2 |

| Flange, Luqunta Alxanka | 6 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIG | 4 |

| Flange, Luqunta Alxanka | 4 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIG | 4 |

| Flange, Luqunta Alxanka | 18 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIG | 2 |

| Flange, Luqunta Alxanka | 8 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIG | 2 |

| Flange, Luqunta Alxanka | 8 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIG | 2 |

Su'aalaha Badiya La Weydiiyo

1. Waa maxay noocyada kala duwan ee tuubooyinka birta aan miridhku lahayn?

Jawaab: Qalabka tuubooyinka birta aan lahayn waxaa ka mid ah qalabka tuubooyinka alxanka dabada, qalabka tuubooyinka alxanka godka, qalabka tuubooyinka dunta leh, flanges, waalka iyo noocyo kale.

2. Waa maxay faraqa u dhexeeya qalabka tuubooyinka birta aan daxalka lahayn ee 304 iyo 316?

A: Bir aan miridh lahayn oo 304 ah ayaa ku habboon codsiyada badankood waxayna leedahay iska caabin aad u fiican oo daxalka ah. Dhanka kale, birta aan miridh lahayn ee 316 waxay leedahay iska caabin daxalka oo ka wanaagsan deegaannada aadka u daxalka badan waxayna ku habboon tahay codsiyada badda iyo kiimikada.

3. Waa maxay faa'iidooyinka isticmaalka tuubooyinka dabada laga sameeyay ee la farsameeyay?

A: Qalabka alxanka dabada ee la been abuuray wuxuu bixiyaa xoog la xoojiyay, isku hallayn, iyo isku xirnaan aan daadanayn. Waxay bixiyaan iska caabin saameyn oo aad u fiican waxaana loo doorbidaa isticmaalka cadaadiska sare iyo heerkulka sare.

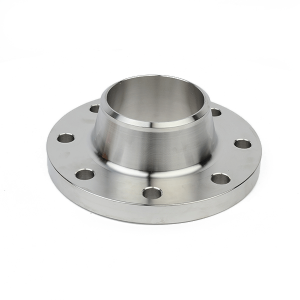

4. Waa maxay flange-ka alxanka dabada?

Jawaab: Flange-ka alxanka dabada waa flange tuubo oo leh xuddun dheer oo la isku dhejiyay oo lagu dhejiyay tuubada. Waxay bixisaa kala-guur siman oo ka bilaabma tuubo ilaa flange oo leh xoog iyo hufnaan aad u fiican.

5. Nooca birta aan miridhku lahayn ee loo isticmaalo tuubooyinka?

A: Bir aan miridh lahayn oo ah 304, 316, 304L, 316L iyo 317 ayaa si caadi ah loogu isticmaalaa qalabka tuubooyinka sababtoo ah iska caabbinta daxalka, cimri dhererkooda iyo kala duwanaanshahooda.

6. Qalabka tuubooyinka birta aan daxalka lahayn ma loo isticmaali karaa codsiyada heerkulka sare?

Jawaab: Haa, qalabka birta aan daxalka lahayn ayaa ku habboon codsiyada heerkulka sare. Si kastaba ha ahaatee, heerka birta aan daxalka lahayn ee la isticmaalo waa in si taxaddar leh loo doortaa iyadoo lagu saleynayo shuruudaha heerkulka gaarka ah ee codsiga.

7. Qalabka tuubooyinka birta aan miridhku lahayn ma ku habboon yihiin warshadaha cuntada iyo cabitaanka?

Jawaab: Haa, qalabka tuubooyinka birta aan miridhku lahayn ayaa si weyn loogu isticmaalaa warshadaha cuntada iyo cabitaanka sababtoo ah nadaafadooda, iska caabbinta daxalka, iyo dayactirkooda fudud.

8. Waa maxay faraqa u dhexeeya qalabka alxanka godka iyo qalabka alxanka dabada?

Jawaab: Qalabka tuubooyinka ee godka lagu tolay waxay geliyaan tuubada godka ka dibna waxay sameeyaan alxanka fillet-ka si ay ugu xidhaan tuubada. Dhinaca kale, qalabka alxanka ee dabada ayaa u baahan in la jaro oo la tolo dhammaadka tuubada.

9. Qalabka tuubooyinka birta aan miridhku lahayn ma dib loo warshadayn karaa?

J: Haa, qalabka tuubooyinka birta aan daxalka lahayn waa kuwo aad loo warshadeyn karo. Birta aan daxalka lahayn waa walxo waara oo dib loo warshadeyn karo oo dib loo isticmaali karo iyada oo aan la lumin sifooyinkeeda ama tayadeeda.

10. Waa maxay faa'iidooyinka isticmaalka tuubooyinka birta aan miridhku lahayn marka loo eego agabka kale?

J: Qalabka tuubooyinka birta aan miridhku lahayn waxay bixiyaan faa'iidooyin badan, sida iska caabbinta daxalka oo aad u fiican, xoog sare, cimri dherer iyo sifooyin nadaafadeed. Waa kuwo dayactir yar, cimri dheer leh waxayna leeyihiin muuqaal nadiif ah oo qurux badan.

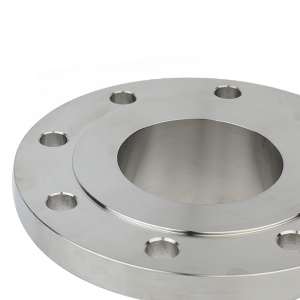

BANDHIG FAAHFAAHINTA ALAABADA

1. Wajiga

Waxaa kor loo qaadi karaa wejiga (RF), wejiga oo dhan (FF), kala-goyska giraanta (RTJ), jeexdin, carrab, ama loo habeyn karaa.

2. Dhammaadka Bevel sida waafaqsan ANSI B16.25

3.CNC si fiican ayaa loo dhammeeyay.

Dhammaadka wejiga: Dhammaadka wejiga flange-ka waxaa lagu cabbiraa Dhererka Xisaabeed ee Celceliska Qalafsan (AARH). Dhammaadka waxaa lagu go'aamiyaa heerka la isticmaalay. Tusaale ahaan, ANSI B16.5 wuxuu qeexayaa dhammaadka wejiga ee u dhexeeya 125AARH-500AARH (3.2Ra ilaa 12.5Ra). Dhammaadka kale waxaa laga heli karaa codsi ahaan, tusaale ahaan 1.6 Ra max, 1.6/3.2 Ra, 3.2/6.3Ra ama 6.3/12.5Ra. Kala duwanaanshaha 3.2/6.3Ra ayaa ugu badan.

CALAAMADAHA IYO BAAKAD-QAADKA

• Lakab kasta wuxuu isticmaalaa filim balaastig ah si uu u ilaaliyo dusha sare

• Dhammaan birta aan miridhku lahayn waxaa lagu buuxiyaa kiis alwaax ah. Haddii aad rabto inaad kaarboonka kaarboonka ah cabbir weyn ku darto baaldi alwaax ah. Ama waxaa lagu beddeli karaa baakad.

• Calaamadda dhoofinta ayaa la samayn karaa marka la codsado

• Calaamadaha alaabta waa la xarri karaa ama la daabacan karaa. OEM waa la aqbalayaa.

KORMEER

• Imtixaanka UT

• Baaritaanka PT

• Baaritaanka MT

• Tijaabada cabbirka

Kahor keenista, kooxdayada QC waxay diyaarin doontaa baaritaanka NDT iyo kormeerka cabbirka. Sidoo kale waxay aqbali doontaa TPI (kormeerka dhinac saddexaad).

HABKA SOO SAARKA

| 1. Dooro walxo cayriin ah oo asal ah | 2. Jar walxaha ceeriin ah | 3. Kuleylinta kahor |

| 4. Samaynta | 5. Daaweynta kulaylka | 6. Makiinadaha adag |

| 7. Qodista | 8. Mashruuc fiican | 9. Calaamadaynta |

| 10. Kormeerka | 11. Baakad | 12. Bixinta |

Kiiska Iskaashi

Mashruuc ka socda Turkiga, flanges-ka waxaa loo isticmaalaa dhuumaha gaaska dabiiciga ah. Dhammaan flanges-kaas waxaa ansixisay TUV.

XAASHIDA XOGTA FLANGE

1. Cabbirka iyo dulqaadka flange-ka waa inay waafaqsanaadaan ASME B16.5.

2. Flanges-ka waxaa lagu soo saari doonaa foorno.

3. Alaabtu waa inay waafaqsanaato heerarka ASTM A105, ASTM A694 F65 iyo ASTM A694 F70.

4. Flanges-ka ASTM A694 F65 iyo ASTM A694 F70 waa in la damiyaa oo la qaboojiyaa.

5. Shahaadooyinka tijaabada agabka iyo warbixinnada daaweynta kulaylka waa in loo diyaariyaa kormeerka TPI.

6. Flanges-ka WN waa inay la socdaan darafyada bevel ee la jaanqaadaya ASME B16.25.

7. Qiimaha tijaabada kiimikada iyo farsamada ee walxaha (saamaynta, wax-soo-saarka, jiidista iwm.) waa inay ahaadaan kuwo waafaqsan heerarka la xiriira.

8. Dhammaan dusha sare waa in lagu farsameeyaa oo lagu rinjiyeeyaa saliid hufan si looga hortago miridhku.

9. Calaamadayntu waa inay ku jirtaa macluumaadka soo socda,

• Dhexroorka (dhammaad. 6")

• Heerka cadaadiska (dhammaad ahaan 150 LB)

• Heerka Agabka (tusaale ahaan ASTM A 105)

• Dhumucda derbiga (dhammaad ahaan 4,78 mm)

• Lambarka Kulaylka (dhammaad 138413)

• Heerka wax soo saarka (ASME B16.5)

10. Alaabtu waa inay ka xorowdaa wax cillado iyo dildilaac ah oo dusha sare ah. Dayactirka alxanka waa mamnuuc.

11. Dhammaan flanges-ka waa in kor loo qaadaa wejiga (RF) oo leh dusha shaabadaysan. Dusha shaabadaysan waa inay noqotaa Ra 3,2 – 6,3 µm (125 – 250 mic. oo ay ku jirto) oo la jaanqaadaya ASME B46.1.

12. Agabka waa in la xidhaa si looga hortago waxyeelada soo gaarta mishiinnada, iyo xidhitaanka dusha sare.

13. Dhammaan cabbiradu waa inay ahaadaan kuwo togan (+). Marka laga reebo dulqaadka waa mamnuuc.

14. Qalabka laalaabka ee flange-ka waa in loo habeeyaa ASME B16.25.

15. Habka wax soo saarka waxaa hubin doona TPI wakhti kasta.

16. TPI waxay ka qaadi kartaa muunado walxo kasta oo loogu talagalay muunadda tijaabada kiimikada/farsamada.

17. Warbixinta kormeerka soo socota waxaa dib u eegi doona TPI.

| Shay | Cabbirka (Inji) | Fasalka Cadaadiska | CS | Alaab | WT (mm) | Goobta | Tirada. |

| SORF | 12 | 150LB | 20 | A105 | - | TANGYADA FLANGES | 48 |

| SORF | 8 | 150LB | 20 | A105 | - | TANGYADA FLANGES | 32 |

| SORF | 3 | 150LB | 20 | A105 | - | TANGYADA FLANGES | 32 |

| Flange, Luqunta Alxanka | 24 | 150LB | 20 | A105 | 14 | TANGYADA FLANGES | 2 |

| Flange, Luqunta Alxanka | 24 | 150LB | 20 | A105 | 5.54 | TANGYADA FLANGES | 4 |

| SORF | 20 | 150LB | 20 | A105 | - | TANGYADA FLANGES | 6 |

| Flange, Luqunta Alxanka | 24 | 150LB | 20 | A105 | 5.54 | TANGYADA FLANGES | 8 |

| Flange, Luqunta Alxanka | 24 | 150LB | 20 | A105 | 14 | TANGYADA FLANGES | 8 |

| Flange, Luqunta Alxanka | 24 | 150LB | 20 | A105 | 16 | TANGYADA FLANGES | 8 |

| SORF | 3 | 150LB | 20 | A105 | - | TANGYADA FLANGES | 24 |

| SORF | 20 | 150LB | 20 | A105 | - | TANGYADA FLANGES | 6 |

| Flange, Luqunta Alxanka | 24 | 150LB | 20 | A105 | 5.54 | TANGYADA FLANGES | 8 |

| Flange, Luqunta Alxanka | 24 | 150LB | 20 | A105 | 14 | TANGYADA FLANGES | 16 |

| Shay | Cabbirka (Inji) | Fasalka Cadaadiska | CS | Alaab | WT (mm) | Goobta | Tirada. |

| Flange, Luqunta Alxanka | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Luqunta Alxanka | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Luqunta Alxanka | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Luqunta Alxanka | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Luqunta Alxanka | 12 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Luqunta Alxanka | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Luqunta Alxanka | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Luqunta Alxanka | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Luqunta Alxanka | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Luqunta Alxanka | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Luqunta Alxanka | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Luqunta Alxanka | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Luqunta Alxanka | 12 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Luqunta Alxanka | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Luqunta Alxanka | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Luqunta Alxanka | 10 | 300LB | 51 | ASTM A694 F65 | 4.78 | PSB1 | 2 |

| Flange, Luqunta Alxanka | 6 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIG | 4 |

| Flange, Luqunta Alxanka | 4 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIG | 4 |

| Flange, Luqunta Alxanka | 18 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIG | 2 |

| Flange, Luqunta Alxanka | 8 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIG | 2 |

| Flange, Luqunta Alxanka | 8 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIG | 2 |

Qalabka tuubooyinka waa qaybo muhiim u ah nidaamka tuubooyinka, kuwaas oo loo isticmaalo isku xirka, dib u habeynta, leexinta, isbeddelka cabbirka, shaabadeynta ama xakamaynta socodka dareeraha. Waxaa si weyn loogu adeegsadaa meelaha sida dhismaha, warshadaha, tamarta iyo adeegyada degmada.

Hawlaha Muhiimka ah:Waxay qaban kartaa shaqooyin sida isku xirka tuubooyinka, beddelka jihada socodka, kala qaybinta iyo isku darka socodka, hagaajinta dhexroorka tuubooyinka, xidhitaanka tuubooyinka, xakamaynta iyo nidaaminta.

Baaxadda Codsiga:

- Biyo-mareenka dhismaha iyo biyo-mareenka:Xusullada PVC iyo PPR tris ayaa loo isticmaalaa shabakadaha tuubooyinka biyaha.

- Dhuumaha warshadaha:Fiilooyinka birta aan lahayn iyo xusullada birta ah ee dahaarka leh ayaa loo isticmaalaa in lagu qaado warbaahinta kiimikada.

- Gaadiidka tamarta:Tuubooyinka birta ah ee cadaadiska sare leh ayaa loo isticmaalaa dhuumaha saliidda iyo gaaska.

- HVAC (Kuleyliyaha, Hawada, iyo Qaboojiyaha Hawada):Qalabka tuubooyinka naxaasta ah ayaa loo isticmaalaa in lagu xiro dhuumaha qaboojiyaha, iyo kala-goysyada dabacsan ayaa loo isticmaalaa yaraynta gariirka.

- Waraabka Beeraha:Xidhiidhiyayaasha degdega ah waxay sahlaan isu-imaatinka iyo kala-furka nidaamyada waraabka rusheeyaha.

-

Qalabka Tuubooyinka A105 Fasalka 150 Ss Kaarboon Bir ah Pl...

-

Cadaadiska Caadiga ah ee Flange-ka ee la been abuuray ...

-

nooca qoorta alxanka birta ah ee 6″ ANSI CLASS...

-

bir kaarboon ah oo ah nooca loo yaqaan 'a105' oo ah nooca 'BL flange'

-

ASTM A182 F51 F53 BL ANSI B16.5 Bir aan miridh lahayn...

-

flange-ka dusha sare ee WN 4″ 900# RF A105 dual gr...