QAYBAHA ALAABTA

| Magaca Badeecada | Daboolka tuubada |

| Cabbirka | 1/2"-60" oo aan tolnayn, 60"-110" oo la alxamay |

| Heerka Caadiga ah | ANSI B16.9, EN10253-4, DIN2617, GOST17379, JIS B2313, MSS SP 75, iwm. |

| Dhumucda derbiga | SCH5S, SCH10, SCH10S, STD, XS, SCH40S, SCH80S, SCH20, SCH30, SCH40, SCH60, SCH80, SCH160, XXS, oo loo habeeyey iwm. |

| Dhammaad | Dhammaadka Bevel/BE/buttweld |

| Dusha sare | la miiray, ciid la duubay, la safeeyey, muraayad la safeeyey iwm. |

| Alaab | Bir aan daxal lahayn:A403 WP304/304L, A403 WP316/316L, A403 WP321, A403 WP310S, A403 WP347H, A403 WP316Ti, A403 WP317, 904L,1.4301,1.4307,1.4401,1.4571,1.4541, 254Mo iyo iwm. |

| Bir aan daxal lahayn oo laba jibbaaran:UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462,1.4410,1.4501 iyo iwm. | |

| Daawaha Nikkel:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H, C22, C-276, Monel400, Alloy20 iwm. | |

| Codsiga | Warshadaha kiimikada batroolka; warshadaha duulista iyo hawada sare; warshadaha dawooyinka, qiiqa gaaska; warshadda korontada; dhismaha maraakiibta; daaweynta biyaha, iwm. |

| Faa'iidooyinka | kayd diyaar ah, waqti gaarsiin degdeg ah; laga heli karo cabbirro kasta, la habeeyey; tayo sare leh |

DABOOLKA BEELAHA BIRTA AH

Daboolka Tuubada Birta ah waxaa sidoo kale loo yaqaan Birta Laalaada, badanaa waxaa lagu dhejiyaa dhamaadka tuubada ama waxaa lagu dhejiyaa dunta dibadda ee dhamaadka tuubada si loo daboolo qalabka tuubada. Si loo xiro tuubada, shaqadu waxay la mid tahay fiilada tuubada.

NOOCA KOOBADA

Noocyada isku xirka, waxaa jira: 1. Daboolka Alxanka Butt 2. Daboolka Alxanka Socket

Daboolka Birta ah ee BW

Daboolka tuubada birta ah ee BW waa nooca qalabka alxanka dabada, hababka isku xidhka waa in la isticmaalo alxanka dabada. Markaa daboolka BW wuxuu ku dhammaadaa godad ama siman.

Cabbirka iyo miisaanka daboolka BW:

| Cabbirka caadiga ah ee tuubada | Debedda Dhexroorka Bevel (mm) | Dhererka E(mm) | Xaddidaadda Dhumucda Darbiga ee Dhererka, E | Dhererka E1(mm) | Miisaanka (kg) | |||||

| SCH10S | SCH20 | Cudurrada Galmada La Isugu Gudbiyo (STD) | SCH40 | XS | SCH80 | |||||

| 1/2 | 21.3 | 25 | 4.57 | 25 | 0.04 | 0.03 | 0.03 | 0.05 | 0.05 | |

| 3/4 | 26.7 | 25 | 3.81 | 25 | 0.06 | 0.06 | 0.06 | 0.10 | 0.10 | |

| 1 | 33.4 | 38 | 4.57 | 38 | 0.09 | 0.10 | 0.10 | 0.013 | 0.13 | |

| 1 1/4 | 42.2 | 38 | 4.83 | 38 | 0.13 | 0.14 | 0.14 | 0.20 | 0.20 | |

| 1 1/2 | 48.3 | 38 | 5.08 | 38 | 0.14 | 0.20 | 0.20 | 0.23 | 0.23 | |

| 2 | 60.3 | 38 | 5.59 | 44 | 0.20 | 0.30 | 0.30 | 0.30 | 0.30 | |

| 2 1/2 | 73 | 38 | 7.11 | 51 | 0.30 | 0.20 | 0.50 | 0.50 | 0.50 | |

| 3 | 88.9 | 51 | 7.62 | 64 | 0.45 | 0.70 | 0.70 | 0.90 | 0.90 | |

| 3 1/2 | 101.6 | 64 | 8.13 | 76 | 0.60 | 1.40 | 1.40 | 1.70 | 1.70 | |

| 4 | 114.3 | 64 | 8.64 | 76 | 0.65 | 1.6 | 1.6 | 2.0 | 2.0 | |

| 5 | 141.3 | 76 | 9.65 | 89 | 1.05 | 2.3 | 2.3 | 3.0 | 3.0 | |

| 6 | 168.3 | 89 | 10.92 | 102 | 1.4 | 3.6 | 3.6 | 4.0 | 4.0 | |

| 8 | 219.1 | 102 | 12.70 | 127 | 2.50 | 4.50 | 5.50 | 5.50 | 8.40 | 8.40 |

| 10 | 273 | 127 | 12.70 | 152 | 4.90 | 7 | 10 | 10 | 13.60 | 16.20 |

| 12 | 323.8 | 152 | 12.70 | 178 | 7 | 9 | 15 | 19 | 22 | 26.90 |

| 14 | 355.6 | 165 | 12.70 | 191 | 8.50 | 15.50 | 17 | 23 | 27 | 34.70 |

| 16 | 406.4 | 178 | 12.70 | 203 | 14.50 | 20 | 23 | 30 | 30 | 43.50 |

| 18 | 457 | 203 | 12.70 | 229 | 18 | 25 | 29 | 39 | 32 | 72.50 |

| 20 | 508 | 229 | 12.70 | 254 | 27.50 | 36 | 36 | 67 | 49 | 98.50 |

| 22 | 559 | 254 | 12.70 | 254 | 42 | 42 | 51 | 120 | ||

| 24 | 610 | 267 | 12.70 | 305 | 35 | 52 | 52 | 93 | 60 | 150 |

SAWIRO FAAHFAAHSAN

1. Dhammaadka qalooca sida waafaqsan ANSI B16.25.

2. Marka hore nadiifi ka hor inta aan la rogin ciidda, ka dibna dusha sare ayaa aad u siman.

3. Iyada oo aan lahayn lamination iyo dildilaacyo.

4. Iyada oo aan wax dayactir ah lagu samayn alxanka.

5. Daawaynta dusha sare waa la miiri karaa, waxaa la rogi karaa ciid, waxaa la dhammayn karaa matte, waxaana la safayn karaa muraayad. Hubaal, qiimuhu wuu ka duwan yahay. Si aad u tixraacdo, dusha sare ee ciidda lagu rogo ayaa ah tan ugu caansan. Qiimaha duubka ciidda lagu rogo wuxuu ku habboon yahay macaamiisha badankood.

KORMEER

1. Cabbiraadaha cabbirka, dhammaantood waxay ku jiraan dulqaad caadi ah.

2. Dulqaad dhumuc leh: +/-12.5%, ama codsigaaga.

3. PMI

4. Baaritaanka PT, UT, iyo X-ray.

5. Aqbal kormeerka dhinac saddexaad.

6. Sahayda MTC, shahaadada EN10204 3.1/3.2, NACE

7. ASTM A262 practice E

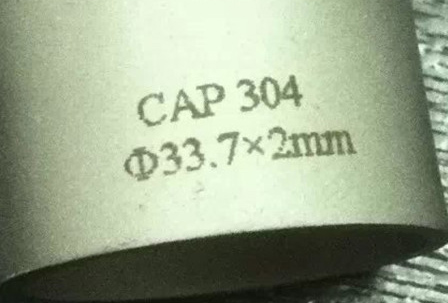

CALAAMAD

Shaqooyin kala duwan oo calaamadayn ah ayaa lagu samayn karaa codsigaaga. Waan aqbalnaa calaamadaynta LOGO-gaaga.

BAAKADAHA IYO raritaanka

1. Waxaa ku xiran kiis alwaax ah ama baaldi alwaax ah

2. Waxaan liiska baakadaha saari doonnaa baakad kasta

3. Waxaan ku dhejin doonnaa calaamadayn rarid baakad kasta. Erayada calaamadaynta waxay ku qoran yihiin codsigaaga.

4. Dhammaan agabka baakadaha alwaaxa ah waa kuwo aan lahayn buufin

Su'aalaha Badiya La Weydiiyo

1. Waa maxay daboolka weelka cadaadiska ee tuubada birta aan la taaban karin ee la isku dhejiyay?

Daboolka tuubada cadaadiska ee dhamaadka tuubada birta aan lahayn ee la alxamay waa qayb loo isticmaalo in lagu xiro dhamaadka tuubooyinka tuubada cadaadiska ee ku xiran alxanka. Waxa laga sameeyay bir aan lahayn, taasoo hubinaysa cimri dherer iyo iska caabin daxalka.

2. Waa maxay faa'iidooyinka isticmaalka daboolka weelka cadaadiska ee tuubooyinka birta aan miridhku lahayn ee la alxamay?

Isticmaalka daboolka tuubada birta aan miridhku lahayn ee lagu dahaadho tuubooyinka cadaadiska leh waxay leedahay faa'iidooyinka xoog sare, iska caabin cadaadis sare, iska caabin heerkul sare, iyo iska caabin daxalka. Waxay hubisaa shaabad ammaan ah waxayna ka caawisaa ilaalinta daacadnimada weelka cadaadiska.

3. Sidee loo rakibaa daboolka weelka cadaadiska ee tuubada birta ah ee aan la taaban karin ee la isku qurxiyey?

Si aad u rakibto dabool tuubo bir ah oo bir aan miridh lahayn oo lagu dahaadhay, isticmaal farsamooyin alxan oo ku habboon si aad daboolka ugu dhejiso dhammaadka tuubada xididdada cadaadiska. Waa muhiim in la hubiyo isku-xidhnaan habboon iyo alxanka oo sugan si loo helo shaabad lagu kalsoonaan karo.

4. Daboolka weelka cadaadiska ee tuubooyinka birta aan la taaban karin ee la alxamay ma laga heli karaa cabbirro kala duwan?

Haa, daboollada weelka cadaadiska ee tuubooyinka birta aan la taaban karin ee lagu dahaadhay ayaa laga heli karaa cabbirro kala duwan si loo daboolo dhexroorka tuubooyinka kala duwan. Doorashada cabbirka saxda ah si loo hubiyo ku habboonaanta iyo shaabadda saxda ah waa muhiim.

5. Daboolka weelka cadaadiska ee tuubada birta ah ee aan la taaban karin ma loo isticmaali karaa codsiyada cadaadiska sare leh?

Haa, daboollada weelasha cadaadiska ee tuubooyinka birta aan lahayn ee birta ah waxaa loogu talagalay inay u adkeystaan codsiyada cadaadiska sare. Waxaa loo sameeyay inay u adkeystaan xoogagga ka dhasha cadaadiska ku jira weelka oo ay ilaaliyaan shaabad adag.

6. Daboolka tuubada birta ah ee aan la taaban karin ee daboolka cadaadiska weelka ma u adkaysta daxalka?

Haa, daboollada weelka cadaadiska ee tuubooyinka birta aan daxalka lahayn ee la alxamay ayaa aad u adkaysta daxalka. Birta aan daxalka lahayn waxaa loo yaqaanaa sifooyinkeeda u adkaysta daxalka, taasoo ka dhigaysa mid ku habboon noocyo kala duwan oo adeegsiyo warshadeed ah.

7. Daboolka weelka cadaadiska ee tuubada birta aan la taaban karin ee la alxami karin ma loo isticmaali karaa noocyada kala duwan ee weelasha cadaadiska?

Haa, daboollada weelka cadaadiska ee tuubooyinka birta aan la taaban karin ee la alxanka leh waa kuwo la isticmaali karo waxaana loo isticmaali karaa noocyo kala duwan oo weelal cadaadis ah, oo ay ku jiraan kuwa loo isticmaalo warshadaha saliidda iyo gaaska, kiimikada iyo dawooyinka.

8. Waa maxay cimriga adeegga daboolka weelka cadaadiska ee tuubada birta aan la taaban karin ee birta ah?

Cimriga adeegga ee daboolka cadaadiska ee tuubooyinka birta aan miridhku lahayn ee lagu dahaadhay waxay ku xiran tahay arrimo ay ka mid yihiin xaaladaha isticmaalka daboolka, dayactirka iyo tayada. Iyadoo la adeegsanayo dayactir habboon iyo kormeer joogto ah, waxay sii jiri karaan sannado badan.

9. Ma jiraan wax taxaddarro gaar ah oo ku saabsan badbaadada marka la isticmaalayo daboolka weelka cadaadiska ee tuubooyinka birta aan miridhku lahayn ee la alxamay?

Marka la isticmaalayo daboollada weelka cadaadiska ee tuubooyinka birta aan lahayn ee la alxanka leh, waa in la raaco taxaddarrada badbaadada, sida isticmaalka farsamooyinka alxanka ee saxda ah si loo hubiyo shaabad adag oo aan daadanayn. Si loo hubiyo badbaadada, waxaad sidoo kale u baahan tahay inaad si joogto ah u hubiso calaamadaha xirashada ama dhaawaca.

10. Daboolka weelka cadaadiska ee tuubada birta ah ee aan la taaban karin ma la habeyn karaa?

Haa, iyadoo ku xiran soo saaraha, daboolka weelka cadaadiska ee tuubooyinka birta aan la taaban karin ee la alxanka leh ayaa loo habeyn karaa si loo buuxiyo shuruudo gaar ah. Xulashooyinka habaynta waxaa ku jiri kara agab kala duwan, cabbirro iyo naqshado si ay ugu habboonaadaan codsiyada shaqsiyeed.

Qalabka tuubooyinka waa qaybo muhiim u ah nidaamka tuubooyinka, kuwaas oo loo isticmaalo isku xirka, dib u habeynta, leexinta, isbeddelka cabbirka, shaabadeynta ama xakamaynta socodka dareeraha. Waxaa si weyn loogu adeegsadaa meelaha sida dhismaha, warshadaha, tamarta iyo adeegyada degmada.

Hawlaha Muhiimka ah:Waxay qaban kartaa shaqooyin sida isku xirka tuubooyinka, beddelka jihada socodka, kala qaybinta iyo isku darka socodka, hagaajinta dhexroorka tuubooyinka, xidhitaanka tuubooyinka, xakamaynta iyo nidaaminta.

Baaxadda Codsiga:

- Biyo-mareenka dhismaha iyo biyo-mareenka:Xusullada PVC iyo PPR tris ayaa loo isticmaalaa shabakadaha tuubooyinka biyaha.

- Dhuumaha warshadaha:Fiilooyinka birta aan lahayn iyo xusullada birta ah ee dahaarka leh ayaa loo isticmaalaa in lagu qaado warbaahinta kiimikada.

- Gaadiidka tamarta:Tuubooyinka birta ah ee cadaadiska sare leh ayaa loo isticmaalaa dhuumaha saliidda iyo gaaska.

- HVAC (Kuleyliyaha, Hawada, iyo Qaboojiyaha Hawada):Qalabka tuubooyinka naxaasta ah ayaa loo isticmaalaa in lagu xiro dhuumaha qaboojiyaha, iyo kala-goysyada dabacsan ayaa loo isticmaalaa yaraynta gariirka.

- Waraabka Beeraha:Xidhiidhiyayaasha degdega ah waxay sahlaan isu-imaatinka iyo kala-furka nidaamyada waraabka rusheeyaha.

-

ASME B16.9 A105 A234WPB Alxanka dabada birta ee kaarboon ...

-

Birta aan miridh lahayn A403 WP316 Butt Weld tuubo Fitti...

-

birta kaarboon sch80 dabada laga tolay 12 inji sch4...

-

bir kaarboon ah oo ah astm a105 reducer concentric ah ...

-

90 darajo xusulka shabaq reducer bir carbon Butt w ...

-

1″ 33.4mm DN25 25A sch10 tuubo xusul ah oo ku habboon...